Sunday, March 10, 2013

World Expo’s Legacy for More Sustainable Cities.

by David B. Sutton, Ph.D.

PART III

Lessons for Sustainable Building

In each of the past issues of EcoNomy, we have been exploring the legacy of Shanghai‘s World Expo of 2010 — the lessons to be learned from the magnificent event. In the first four issues, we discussed the massive environmental efforts that Shanghai itself underwent in preparations of this World event. We explored how the Expo accelerated Shanghai’s long term efforts in making itself a more sustainable city and provided additional momentum to strengthen its various environmental initiatives including the development of one of the best (if the not THE BEST) megacity public transit metro system in the World.

Then in subsequent issues, we continued to explore the many unextolled virtues occurring at the Expo Park itself. Using an integrative model focusing on energy, transportation, water and waste management systems, the Expo planners developed the infrastructure for a “City within a City” on the Expo site. We looked at the unique Expo Axis, magnificent public buildings and constructed wetlands that remain to serve the City and its people for years to come.

Here we will turn to some truly integrated demonstrations of sustainable urban building occurring in the Expo’s Urban Best Practices Area where perhaps the best lessons for sustainable building can be learned.

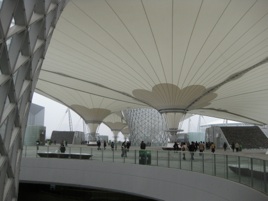

The Urban Best Practices Area

The Expo organizers set up the Urban Best Practices Area (UBPA) to collect and showcase successful attempts at making cities more livable and sustainable. The UBPA enabled cities around the world to take part in the Expo for the first time in history. The area served as a platform for these cities to share and exchange experiences in urban construction and development. The UBPA was divided into four exhibition fields, namely Livable Cities, Sustainable Urbanization, Protection and Utilization of Historical Heritage Sites and Technological Innovation in the Built Environment. (1)

Sustainable Building

Sustainable building is as much about the process of design and construction as it is about the created structures themselves. The process of creating sustainable buildings in which we live, work and play is about being conscious of the surroundings and impact, designing in accord with natural conditions (climate and resources) on-site and applying the most responsible and appropriate materials and technology (2).

Fully Integrated Design requires thinking of whole systems integration at the conceptualization, planning and DESIGN phase before even talking about deploying new technologies and monitoring on-going operations. Good design solutions can double the efficiency with which we use materials and energy and they are much cheaper than increasing energy supply, quicker, safer and of more lasting benefit. Implementing them is also more labor –intensive (3).

A sustainable building process emphasizes a “Do more with Less” philosophy where the first line of attack is to reduce demand through thoughtful design and then to seek to meet the ultimate need with elegant frugality of energy and trouble, using our best technologies (ingenuity) to wring as much function as possible from each unit of energy use.

Buildings built according to these design principles reduce the need for mechanical heating and cooling by using “natural energy” available from the climate at the building site. The sun, wind, precipitation and the resulting temperatures in the air and stored in the ground and bodies of water create sources of natural heating and cooling energy. These free sources should be considered throughout the full design decision process – site planning, building massing and planning, and finally in the detailed design of building envelop and openings.

Enhancing the building envelope — the separation between the interior and the exterior environments of a building – through increased insulation, multi-glazed windows, green roofing and other passive solutions is a critical first approach to reducing heat gain or loss. Then and only then should the most “appropriate technology” be used to meet the remaining demand.

While the Expo itself once again failed to educate the public as to these sustainable deign principles, thankfully several of the individual installations did a wonderful job of informing the public about what is possible. Detailed discussions of their planning, design, construction process as well as visible monitoring of on-going operations were readily available for visitor viewing. And quite fortunately several of these wonderful fully functioning buildings still remain and are available for future education.

Amongst the many notable examples of isolated sustainable building practice, those who made the effort to develop fully integrated installations stood out. It is these that I will focus on here. In my exhaustive survey of best practice at the Expo, I found BROAD to be the most comprehensive and laudable example. Nobody represented this fully integrated sustainable building process better than the BROAD Pavilion.

BROAD Pavilion

In a previous article I discussed that, as a leading Chinese air conditioning company, Broad provided air conditioning for 200 Expo pavilions. At the Broad Pavilion they illustrated how the system works — using a flame from burning natural gas, heat is changed directly into cooling, a process which is more than twice as energy efficient as conventional systems that require five energy conversions to produce cooling. Broad’s systems were estimated to have reduced the Expo’s CO2 emission by 73,000 tons.

BROAD also used their Pavilion at the World Expo to launch its new Sustainable Building Division. They assembled their factory pre-fabricated Pavilion in just 24 hours at the Expo site using one-sixth the materials and producing 1% of the wastes in construction. The lightweight design, combined with steel diagonal bracing structures, made the building impressively resistant to a Magnitude 9 earthquake. The pavilion included an interactive simulation room where visitors can feel the power of such an earthquake.

One of the most laudable features of the Pavilion, to me, was the clear explanation they made available to visitors to understand the energy and materials saving features that had been so carefully designed into the structure.

Using a combination of Super-insulation in walls and roof (150mm thickness), Triple-glaze windows (100% more effective than double pane for energy savings, 4 times more effective than single pane), Non-conducting window trim, external solar shading, LED (light-emitting diode) lighting, super efficient gas-fired air-conditioning and a fresh air heat recovery system, energy consumption was reduced to 45kwh/sq.m/year, a savings of 80%.

The Pavilion was equipped with their cutting-edge air purification system

where air-circulated inside the pavilion underwent 3 stages of purification, at efficiency rates approaching 95-99%, before distribution. The air is exchanged 1 to 2.5 times per hour and is 20 times cleaner than the surrounding outdoor air.

This fundamental sustainable design philosophy is clearly reflected throughout the BROAD Company Culture. In recent years all buildings at the BROAD Corporate Headquarters in Changsha, where 1,800 hundred employees live and work, were retro-fitted with super insulation, triple pane

windows and heat recovery systems reducing energy consumption by 80 %.

Since the Expo, time-lapse videos of BROAD’s more recent large sustainable building constructions have gone viral on the internet.

One showing the construction of a 17-floor New Ark Hotel at the Company’s Changsha Headquarters (assembled in 90 hours), and another featuring the thirty-floor Hotel on Lake Dongting in Hunan Province (completely assembled in 15 days).

It is sobering to reflect on the impact that such building techniques could have on reducing the energy needed for construction and operation of new buildings worldwide.

Hamburg House

The Hamburg House, known as the Home of Hidden Energies –a name emphasizing the fact that often energy saving design solutions and alternative technologies are not visible to the untrained eye—is the first officially certified “passive energy house” in China, perfectly suited to the climate and local conditions of urban Shanghai.

The Pavilion began its discussion of all the design features going into this passive house (there are information monitors on every floor) with a discussion of their three-tiered design process. First they analyzed the overall energy requirement and designed to reduce it, second they raised the efficiency of using locally available resources after which they used the best renewable energies available – the essential sequential steps in a sustainable design process.

One of the basic requirements of a passive energy house is the maximum reduction of heat loss during winter and a minimum heat input during warm summer periods. The crucial first steps in order to guarantee highly efficient energy saving is the well insulated and totally hermetic building envelope.

The building exterior of the Hamburg Pavilion has a relatively small surface area compared to its interior, one of the main reasons for the relatively low rate of heat loss in the winter and temperature preservation in the summer. The building has a double shell exterior with an insulation layer of polystyrene between the inner concrete layer and outside layer of brick.

Windows on the house are oriented to maximize sunlight usage, especially in the winter, and to preserve a constant indoor temperature of 26°C. The windows face north and east, with shading attained through high-class glazing and a sunscreen film on the windows, which reacts to the altitude of the sun and provides 70% of needed shading. Segments of the building jut out from the surrounding façade like drawers, further increasing the area of north-facing windows. This allows for full solar exposure in winter when the sun is low on the horizon, and limits the sun radiation in the summer when the sun is high.

Geothermal Heating and Cooling

The Hamburg Pavilion provides a working display of how the inexhaustible, natural heat lying beneath the ground can be extracted using a geothermal heat pump located in the basement and used sustainably for both heating and cooling. The system uses geothermal energy to heat a network of water ducts located 35 meters underground. Using the heat pump and exchanger, the hot water is converted into warm air which is pumped to the surface and distributed throughout the building. The cooling system also uses geothermal energy, using the heat pump and exchanger to cold water to as low as 16°C, as needed during warm periods. In times of only moderate heat, however, natural coldness from the ground surface can be used for cooling without the aid of the heat pump. In extremely warm temperatures, the Hamburg Pavilion can also draw on energy from the cooling network of the Urban Best Practices Area, which is driven by a central heat pump and the water of the Huangpu River.

The Hamburg Pavilion includes a highly effective ventilation system which not only provides fresh air for the building, but is also able to recover “waste heat.” A device located on the rooftop is equipped with a highly efficient temperature recovery system which is able to warm up or cool down exhaust air from the building. The fresh air is pumped in, dehumidified, and transported throughout the building through an intricate system of insulated ducts. Before distribution into rooms from beneath the floor, a micro filter cleans the air of micro particles, dust, and pollen. The exhaust is then sucked out through a system of ducts and transported back to the rooftop heat exchanger.

The Hamburg Pavilion rooftop is host to 360 m2 worth of photovoltaic solar panels composed of monocrystalline silicon (a highly efficient silicon), which provide 55% of the required energy for the pavilion.

London’s ZED Pavilion

ZED is short for ‘zero (fossil) energy development’ – a term popularized by the award-winning Beddington ZED (or BedZED), a development of ‘zero carbon’ live/work units in the London Borough of Sutton. Though modest in size, BedZED’’s holistic approach to sustainability has attracted admirers from around the world.

The London ZED Pavilion was designed to bring this approach to the attention of China and millions of visitors from around the World.

A characteristic fixture of a ZED development is their signature Rooftop Wind Cowls. The Pavilion’s rooftop is equipped with rotating “wind cowls”, which automatically determine the prevailing wind direction and capture the wind energy for indoor ventilation use, greatly reducing the energy usage compared to traditional ventilations systems. At a thermal efficiency rate of over 50%, this system is capable of ventilating an area of 450m3/hour at wind speeds of 2.5m/s.

The ZEDFactory Wind Cowl works like an active ventilation system, having dedicated inlet and outlet ducts and a heat recovery system, but instead of using electric fans to drive the air flow it uses the wind to create both positive pressure at the inlet and negative pressure at the outlet, ensuring a throughput of air with no electrical input. In low wind conditions it will continue to produce reasonable ventilation levels through a stack effect.

The Pavilion’s wall and floor are super-insulated and composed of several layers of material which combines concrete and fly ash (a residue left after coal combustion) with highly-insulating XPS boards (extruded polystyrene foam insulation).

The exterior of the Pavilion is covered with a silica dioxide nano-coating, which is capable of reflecting 92% of exterior heat energy. This powerful insulation saves vast amounts of energy and provides for a warm-winter, cool-summer effect.

All the floors in the ZED Pavilion, which will be retained in Shanghai after the Expo as a “Zero Carbon Museum”, are made of high-quality Canadian hardwood certified by the FSC (Forest Stewardship Council), ensuring that the forests from which the wood came are managed in a responsible, sustainable way.

Much of the roof of the pavilion is covered with plants which were chosen for their high rate of car-bon sequestration. The greenery is irrigated by an efficient drip system at the rate of 0.5L/day/m2. The design is not only visually pleasing, but also provides insulation for the building, reducing the energy required for cooling and heating.

In addition to greenery, the rooftop is also covered by 400m2 of solar photovoltaic panels, which directly transform solar radiation into electricity for the pavilion (peak output power of 64kW).

Also located on the rooftop are solar water heaters with a capacity of 6t/day. The heaters are made of glass vacuum tubes which convert solar energy into heat energy. The difference in water temperature between the sunny and the dark sides of the tubes creates microcirculation, as the hot water rises and cold water sinks. This energy provides not only daily hot water demands, but also power which can be used to freshen and dehumidify incoming air.

Rainwater is captured by pipes on the rooftop and terrace and released to underground tanks on the west and south sides of the building, where it is treated and stored for later use. The system is capable of capturing water at a rate of 5 m3/hour, or as much as 1880 m3/year, enough for 60% of construction water needs.

An “energy tree” located on the ZED pavilion rooftop is equipped with 3 monocrystalline silicon solar panels (450W) as well as two wind turbines (60W). The energy created from the tree can be used for internal electricity or stored in batteries via a wind-solar hybrid controller.

Through an intricate system connected to electricity, water, gas, and integral flow meters, ZED pavilion is able to conveniently and effectively monitor and analyze energy usage and loss, enabling them to make better decisions. The system, which can be accessed and controlled from remote locations, can also monitor CO2 emissions and the generation capacity of the pavilion’s renewable energy.

Shanghai Eco House

This is considered to be the first zero energy building in China, achieved successfully by applying a large array of solar energy and other technologies. The building is designed to make efficient use of rainwater and sewage, natural ventilation, and geo-thermal energy. Systems of shutters and flowing liquids in the walls of the building can regulate and adjust inside temperature.

The buildings are constructed in a north-south orientation, providing the room with a pleasant breeze. The top of the stairwell is equipped with an air draft machine, which strengthens vertical ventilation. A simulation demonstrates the effectiveness of the natural ventilation during spring and autumn.

In keeping with its commitment to using as few virgin resources as possible, developers designed the interior and exterior wall using reclaimed construction waste material. These materials included cement made from sludge, recycled waste aggregate, eco-concrete, and fly ash mortar. The façade is covered with an insulating coating comprised of inorganic insulation mortar, while the interior wall uses a combination of gypsum and other composite materials.

Combined with the use of LED lighting, the Eco Home takes full advantage of Natural daylight to illuminate the interior. In fact, over 75% of the interior lighting in major functional rooms comes directly from the sun. The Eco Home has also adopted a localized lighting management system in order to save energy and improve lighting quality. When indoor lighting levels are below normal, panels on the roof automatically adjust to let in more natural light.

The roof of the Shanghai Eco Home is equipped with a 1-kW fuel cell, located at the center of a smart energy system, which man-ages electricity use throughout the house. This system also increases energy efficiency by recycling the exhaust from electricity generation to heat the home’s water.

The Shanghai Eco Home created an integrated pre-fabricated multifunctional balcony on the south side of the building, matching the interior layout and style of the pavilion. Several parts of the balcony, including the flat plate energy collector, solar photovoltaic panels, and communication circuits, were premade in the factory before being assembled at the Expo site, thus consuming less time and increasing the efficiency of construction.

The Eco Home is equipped with Building-Integrated Photovoltaics (BIPV) installed both on the roof and the southern wall. The capacity of the pavilion’s photovoltaic system reaches roughly 12 kW. The system uses a locally made amorphous silicon battery which, compared to conventional mono- or polycrystalline silicon batteries, has a stronger capacity under higher temperatures or fainter light conditions. The PV (photovoltaic) system installed on the southern wall was also prefabricated before on-site assembly.

The Shanghai Eco Home project demonstrates new technology to reduce waste, both organic and inorganic, by transforming it into hazard-free, 100% recycled construction materials (including roadbed materials, building mate-rials, pavement stones, and other materials).

The Pavilion has adopted a central building management system which controls energy management, environmental monitoring, and equipment management. Also installed is an information system which uses infrared technology to monitor the flow of visitors in the pavilion.

Madrid Pavilion

The Madrid Pavilion represents a social housing concept currently implemented in Madrid, Spain. Many eco-technologies appearing in their housing developments were demonstrated in the Pavilion.

The most exciting feature of the Madrid Pavilion is the Air Tree – an exact replica of the creative, groundbreaking structures developed by Urban Ecosystems in Madrid. These circular, hollowed, state-of-the-art pavilions serve not only as a nursery for small trees, but also provide a cool haven for visitors.

The Air Tree, made entirely of 100% lightweight recycled materials, creates oxygen for the surrounding environment and lowers the temperature as much as 10°C. To do this, the top of the “tree” intakes hot air and filters it through a solar-powered humidifier. Once cooled, the air sinks down several long tubes and is released into the pavilion, to the joy and relief of visitors. The Air Tree runs entirely on solar energy, creating not only enough energy for itself, but also access energy to sell back to power companies if needed.

The Solarvoltaic Atrium, equipped with membrane-lined sides which let air out but prevent water from entering, enables the Madrid Pavilion to “breathe” and allows for optimal use of lighting and ventilation. This skylit atrium, whose architectural scheme and electrical system were developed by OnyxSolar, is made of 50 semi-transparent thin-film solar photovoltaic panels produced by Unisolar. The ceiling lets sunlight filter in, which produces 0.8kW of energy that is stored in batteries to power the ornamental fountain jet and light up the roof at night. This first-of-its-kind atrium can reduce nearly 1,500 kg of carbon emissions per year.

At the Madrid pavilion, a series of Unisolar solar thermal collectors is used to cool a 72-m2 room. The system captures the sun’s energy to heat a water circuit located in the ceiling panels, which is then converted into cold air by a thermochemical transformer developed by ClimateWell. The system, also integrated with technology from Uponor, is capable of storing cold air for later use and can cool a 200-m2 house, reducing CO2 emissions by 15,000 kg/year.

A 480-m2 area of the pavilion’s terrace is completely waterproofed, using rainwater to form a 20,000-L reservoir. Half the area is covered by insulating paved stones produced by Losa Filtrón, while the other half is devoted to a rooftop garden combined with a system of photovoltaic solar modules. The garden, developed by Intemper, is comprised of six plant species, specifically chosen by Madrid’s Royal Botanical Garden due to their suitability for Shanghai’s climate. The green space not only provides a pleasant environment, but also sequesters carbon and insulates the building. This highly efficient ecological rooftop saves 37% energy usage.

The Madrid Pavilion’s 41-m2 green façade is not only visually attractive, but also offers insulation and natural protection from the weather, thus reducing the energy required to cool the interior of the pavilion. This low-maintenance vertical garden, which minimizes water use and can be conveniently produced in a factory, is just one of many innovative solutions Madrid has developed, putting the Spanish capital at the forefront of bioclimatic architecture.

Alsace Case Pavilion

The French Region of Alsace, together with the cities of Strasbourg and Mulhouse and Electricité de France (EDF), presented their best technologies and urban practices at the Alsace Pavilion, designed by the Alsace Architectural Design Institute (AADI). Built using solar and water wall technology, the “Waterskin House” presents several strengths of sustainable development in the Alsace Region, including transport, renewable energies, low consumption building, and eco-industry.

The Alsace Case Pavilion presents a unique, visually pleasing innovation along one if its walls, which makes use of solar radiation to regulate the temperature inside the building. The wall is equipped with an inner layer of solar photovoltaic panels, covered by an outer layer of glass prism windows. During the winter, the windows are tilted open, allowing the cold air to enter through the bottom and be heated by the concentrated sunlight in the prisms before entering the building.

During the summer, water cascades continuously down the façade and is evaporated by the concentrated sunlight, thus producing a mist and cooling the air before it enters the building. Additionally, the glass windows change their degree of opening based on the amount of sunlight. As the windows open wider, a shadow is created, thus reducing sunlight heat.

Just next to the Solar Waterskin Wall is a large covering of ascending lush greenery, which is not only easy on the eye but also provides year-round insulation, thus reducing energy usage.

CONCLUSION

It has become a recurring theme in my writing on the preparation and conduct of Shanghai’s World Expo that there was a significant lack of real substantive reporting on technological innovations occurring at the World event. And seemingly little desire to educate the public as to the theme of developing more sustainable cities and the many demonstrations of the means from around the world to achieve such needed habitats. Many of the wonderful things occurring at the Expo were never reported on, discussed, made clear and visible to the visiting public. This represented a clear failure of the public information and education function and a lost opportunity of incalculable value.

Fortunately this was partially remedied by many of the demonstrations in the UBPA area, where the installations themselves did a remarkable job of fully reporting on their process of design, development and operation of their respective site. It is also fortunate that many of these learning centers remain to carry on the education task

It was here that the Expo lived up to its promise of demonstrating what is possible and pointing the way to more sustainable Better Cities for Better Lives.

Notes:

(1) The UBPA presented various on-going practices, along with some experimental examples which have huge application potential. A total of 59 exhibition cases, covering 28 countries and 54 cities from all over the world, were selected for the exhibition. Many of the projects demonstrated cutting edge eco-designs and green building technologies providing valuable lessons for sustainable building.

(2) In, “Thinking and Designing for Sustainability” I have discussed in detail the need to think through the problem and goal and designing before you start searching for the technological solution. (See MovingEcoForum, 26 August 2010).

(3) When properly calculated the additional capital costs in increasing energy efficiency in new buildings, especially commercial ones is often NEGATIVE, i.e. savings on the heating and cooling equipment more than pay for the modifications.

Years ago the American Institute of Architects demonstrated that optimizing performance through integrated planning and design in new buildings can save 50 percent or more in office buildings and 80 percent in some new houses. They concluded in their study that improved design of new buildings and modification of old ones could save a third of current TOTAL national energy use – and save money too. The payback time would be only half that of the alternative investment in increased energy supply, so the same capital could be used twice over.